Usage Areas of PPS

Polyphenylene sulphide (PPS) is a high performance engineering polymer widely used in various industries thanks to its superior properties. PPS, which stands out with its high temperature and chemical resistance properties, is an indispensable material especially in the automotive, electronics, aerospace and medical sectors. In this article, we will examine the usage areas of PPS in detail.

PPS in Automotive Industry

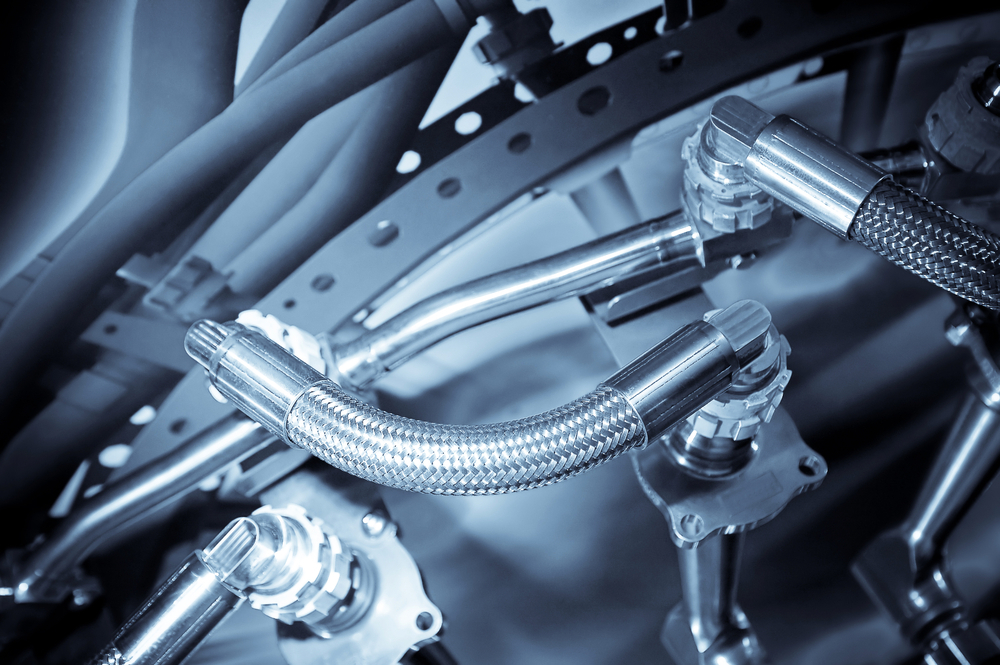

PPS is a favoured material in the automotive industry. Its ability to withstand high temperatures and chemical resistance makes it ideal for engine and engine parts. It offers long-lasting performance especially in automotive components operating in hot and corrosive environments.

Engine Parts: PPS is used in engine parts exposed to high temperatures. Critical parts such as valves, pumps and fasteners are produced with PPS to increase durability.

Electrical Parts: PPS is preferred for electrical connectors and sensors as it provides excellent electrical insulation.

Fuel Systems: Thanks to its chemical resistance properties, PPS is used in pipes and fittings used in fuel injection systems.

PPS in Electronic Industry

Materials used in the electronics industry must have high temperature and electrical insulation properties. PPS fulfils these requirements perfectly. It is preferred in electronic devices, especially for the protection of sensitive circuits.

Circuit Boards: Thanks to the excellent electrical insulation properties of PPS, it is widely used in the production of insulating materials used in circuit boards.

Connection Elements: Connection parts of electronic devices can operate under high temperatures and may be exposed to chemicals. PPS offers reliable performance by maintaining its durability even in these harsh conditions.

Connectors: PPS maintains dimensional stability even during heat treatment, which ensures accurate and reliable operation of electronic connectors.

PPS in the Aerospace Industry

The aerospace industry expects high performance and durability from the materials used. PPS’s resistance to high temperatures and chemicals makes it an excellent choice for applications in this field. In addition, since PPS is a lightweight material, it is widely used in aircraft and spacecraft components where weight must be minimised.

Structural Components: PPS is used where exposed to high temperature and chemical effects, such as aircraft engines and structural parts.

Insulation and Coating Materials: PPS is a preferred material for electrical insulation and thermal coating applications. The outer surface coatings of cables used in aviation are reinforced with PPS.

Lightness and Strength Balance: The high strength-to-weight ratio of PPS makes it one of the lightweight and durable materials used in the aerospace industry.

PPS Usage in Medical Sector

Medical devices require materials that can withstand sterilisation processes and have chemical resistance. PPS fulfils these requirements and is widely used in various medical equipment. It is also safe in contact with the human body thanks to its biocompatibility.

Sterilisation Equipment: PPS is resistant to harsh conditions such as high temperature and steam sterilisation. Therefore, it is frequently used in medical devices and sterilisation equipment.

Prostheses and Implants: The biocompatible properties of PPS enable its use in medical devices and prostheses. In addition, its mechanical durability ensures long-lasting use.

Surgical Instruments: The hard and durable structure of PPS allows it to be used in the production of surgical instruments. Its resistance to chemicals ensures that these instruments remain sterile.

PPS Usage in Other Industries

PPS is a polymer with a wide range of uses and finds a place in many different sectors. It can be used in many areas from industrial equipment to consumer electronics.

Chemical Industry: Equipment such as pipes, valves and gaskets used during chemical processes are long-lasting and reliable thanks to the chemical resistance of PPS.

Water Treatment Systems: PPS is used in filter systems and pipelines used in water treatment plants. It offers long-term performance thanks to its high temperature and chemical resistance.

Food Processing Equipment: In the food industry, PPS is used in equipment operating under high temperature. Suitable for contact with food, PPS can work under hygienic conditions.

Future of PPS

The high performance properties of PPS will enable it to be used in more sectors in the future. Especially the increasing demand for sustainable and environmentally friendly materials may increase the popularity of PPS. The need for lighter, durable and chemically resistant materials will strengthen the place of PPS in industries.

In conclusion, PPS has a wide range of uses and will continue to find a place in new industries in the future.